Mumakore achangopfuura, nekushandiswa kwakakura kwema graphite molds, kukosha kwekushandisa kwepagore kwema molds muindasitiri yemuchina inguva kashanu yehuwandu hwese hwese mhando dzematurusi emuchina, uye kurasikirwa kukuru kwekupisa kunopesana nehurongwa huripo hwekuchengetedza simba muChina.

Sekureva kweongororo, nekuda kwekuumbwa kwezvinhu uye mitengo yesimba yakakwira zvakanyanya uye zvimwe zvikonzero, purofiti yeindasitiri yechigadzirwa yakadonha gore rapfuura; Kuti vararame nekusimudzira, mabhizinesi mazhinji anotora.

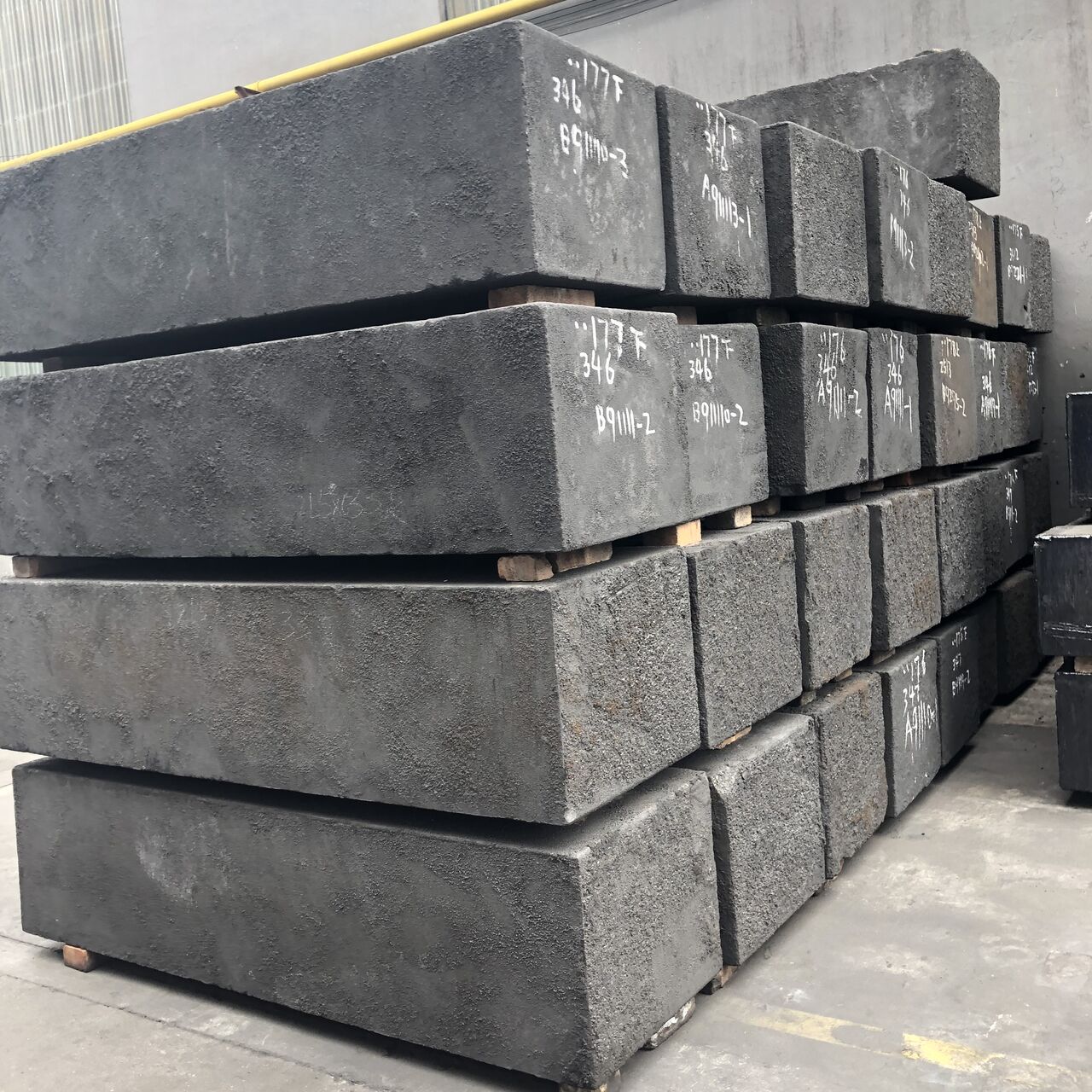

Kuchinja kwezvinhu kunoshandiswa seyero huru yeshanduko nekusimudzira. Zvinonzwisiswa kuti makambani mazhinji akatanga graphite spark discharge zvinhu, mukugadzira mold iri kuita basa rakakosha kwazvo. Zvichienzaniswa neyechinyakare mhangura mold, graphite zvinhu zvine zvakanakira machining akanyanya uye kunaka kwepamusoro pekuita, kunyanya mugomba rekugadziriswa kwechokwadi, rakaomarara, rakatetepa madziro ane mhangura yakakura, bhenefiti yemhangura ine madziro akaomarara. sekushandisa kushoma, kukurumidza kuburitsa kumhanya, huremu huremu uye diki yekupisa kwekuwedzera kweyekupisa, saka electrode yemhangura yave zvishoma nezvishoma yave iyo huru yezvinoyerera zvigadzirwa.Mukupesana, graphite electrode zvinhu zvine zvinotevera zvitanhatu zvakanakira:

1. Kukurumidza kukurumidza;Kubuda kwegraphite kwakakurumidza 2-3 kupfuura mhangura, uye zvinhu hazvisi nyore kukanganisa. Iine mabhenefiti ari pachena mukugadziriswa kweye electrode yakaonda yakasimbiswa. Iyo yekunyorovesa poindi yemhangura yakatenderedza 1000 madhigirii, uye zviri nyore kukanganisa nekuda kwekupisa.

2. Huremu hwakareruka;Kuwanda kwegraphite kunongova 1/5 chete yemhangura. Kana electrode yakakura ichigadziriswa nekubuda, mutoro wemuchina wekushandisa (EDM) unogona kuderedzwa zvinobudirira, unonyanya kukodzera kushandiswa kwehutu hombe.

3. Kuraswa kudiki;Sezvo mafuta espark aine maatomu eC, tembiricha yakakwira inoita kuti maatomu eC ari mumafuta anotsvedza aparadzwe panguva yekuyerera, uye firimu rekudzivirira rinoumbwa pamusoro pegraphite electrode, iyo inotsiva kurasikirwa kwegraphite electrode.

4. No burrs;Mushure mekunge electrode yemhangura yagadziriswa, maburrs anoda kubviswa nemaoko. Nekudaro, hapana mabhura mushure mekunge graphite yagadziriswa, iyo isingangochengete mari yakawanda uye manpower, asi zvakare inoita kuti zvive nyore kuona otomatiki kugadzirwa.

5. Easy polishing;Nekuti kuchekwa kwegraphite kunongova 1/5 chete yemhangura, zviri nyore kugaya nekupukuta nemaoko.

Vi. Mutengo wakaderera;Nekuda kwekukwira kwemutengo wemhangura mumakore achangopfuura, mutengo we graphite muzvinhu zvese wakadzikira pane uya wemhangura.Pasi peiyo vhoriyamu imwechete yeOriental carbon's universality, mutengo wezvigadzirwa zvegraphite wakaderera ne30% kusvika 60% pane wemhangura, mutengo wacho wakadzikama, uye iyo yenguva pfupi inoenderana nekugadzirisa mutengo kudiki kwekuchengetedza uye kuchengetedza kwesimba kudiki. indasitiri yekugadzira, graphite electrode zvinhu zvichachinja zvishoma nezvishoma mhangura electrode uye ichaita basa rinokosha muEDM.Saizvozvowo, mumakwikwi anowedzera anotyisa mumusika wekuumbwa nhasi, kushandiswa kwepamusoro-soro teknolojia yekugadzira zvigadzirwa zvemhando yepamusoro ndiyo nzira yakanakisisa yemakambani ekukunda mumusika uye vatengi.

Nguva yekutumira: Mar-10-2021