Parizvino, matanho makuru ekuderedza kushandiswa kwe electrode ndeaya:

Optimize simba rekupa system parameters. Magetsi emagetsi maparamendi ndizvo zvakakosha zvinokanganisa kushandiswa kwe electrode. Semuenzaniso, kune 60t choto, apo yechipiri rutivi rwemagetsi i410V uye ikozvino iri 23kA, kushandiswa kwemagetsi epamberi kunogona kuderedzwa.

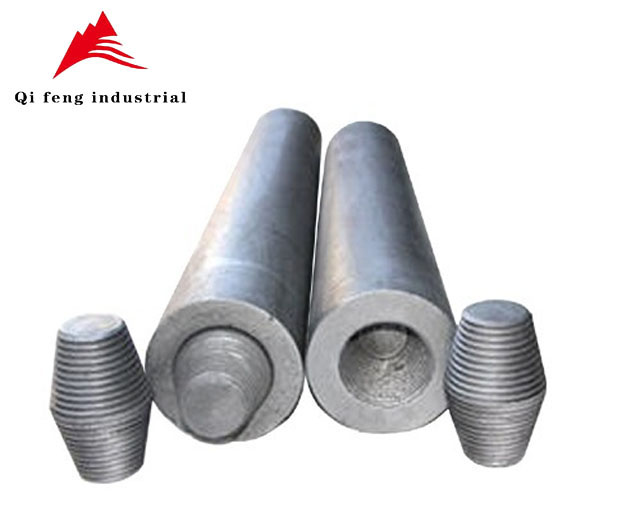

Mvura-yakatonhodzwa composite electrode inogamuchirwa.Mvura-yakatonhorera composite electrode rudzi rutsva rwe electrode yakagadzirwa kunze kwenyika mumakore achangopfuura. Mvura yakanyoroveswa yakasanganiswa electrode inoumbwa nepamusoro pemvura-yakanyoroveswa simbi chubhu chikamu uye yakaderera graphite kushanda chikamu, uye mvura-yakanyoroveswa chikamu chinotora 1/3 yehurefu hwe electrode. Sezvo pasina kupisa kwekushisa kwepamusoro (graphite oxidation) mumvura yakanyoroveswa yesimbi chubhu chikamu, electrode oxidation inoderedzwa, uye mvura-yakatonhorera simbi chubhu chikamu chinochengetedza kushamwaridzana kwakanaka ne gripper. Sezvo tambo yemvura-yakatonhorera chikamu uye graphite chikamu inotora mvura-yakatonhorera mhando, chimiro chayo chakagadzikana, pasina kukuvara, uye chinogona kumira torque yakakura, iyo inovandudza simba reiyo electrode interface, nokudaro zvakanyanya kuderedza kushandiswa kwe electrode.

Anti-oxidation nzira yemvura spray graphite electrode inogamuchirwa. Tichifunga nezvekushandiswa kwemaelectrodhi mukunyungudutsa, matanho ehunyanzvi ekupfapfaidza mvura yegraphite electrode uye kudzivirira oxidation anotorwa, kureva kuti, mhete yekupfapfaidza mvura inotorwa pazasi pe electrode griper kupfapfaidza mvura pamusoro peelectrode surface, kuitira kuti mvura inoyerera ichidzika pasi peelectrode pamusoro, uye mhete yemhete inoshandiswa kuridza mhepo yakamanikidzwa kusvika pamusoro pemvura inoputira pamusoro pemvura yazvino. kuyerera kwemvura. Uchishandisa nzira iyi, kushandiswa kwetoni simbi electrode kwakadzikira zviri pachena. Iyo tekinoroji nyowani inotanga kuiswa mu-ultra-high simba remagetsi muvira. Mvura yekupfapfaidza electrode nzira iri nyore, iri nyore kushanda uye yakachengeteka.

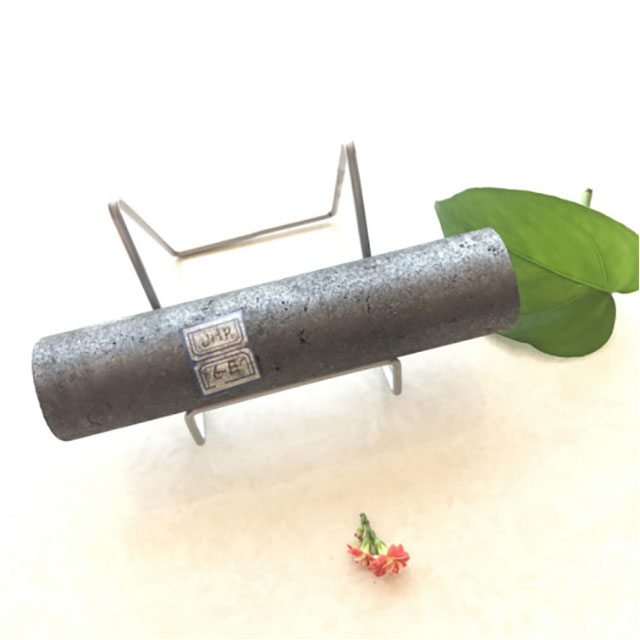

Electrode surface coating teknolojia. Electrode coating tekinoroji inzira iri nyore uye inoshanda yekudzikisa kushandiswa kwe electrode.

Iyo inowanzoshandiswa electrode coating materials iaruminiyamu uye zvakasiyana-siyana zveceramic zvinhu, zvine simba oxidation kuramba pakupisa kwepamusoro uye zvinogona kunyatsoderedza kushandiswa kweoxidation padivi re electrode.

Dip electrode inoshandiswa. Dip electrode ndeyekunyika electrode mumakemikari agent uye kuita kuti pamusoro peelectrode idyidzane neajenti kuti ivandudze kuramba kweelectrode kusvika pakukwira kwetembiricha oxidation. Kushandiswa kwe electrode kunodzikiswa ne10% ~ 15% zvichienzaniswa neakajairika electrode.

Nguva yekutumira: Aug-10-2020