Nheyo yekushanda ye-ultra-high power (UHP) graphite electrodes inonyanya kuenderana nearc discharge phenomenon. Nekushandisa kwavo kwakasarudzika magetsi conductivity, yakakwirira-tembiricha kuramba, uye michina zvimiro, maelectrode aya anogonesa kushandurwa kwakanaka kwesimba remagetsi kuita simba rinopisa mukati menzvimbo dzekunyungudika kwepamusoro-soro, nekudaro kutyaira iyo metallurgical process. Pazasi pane ongororo yakadzama yemaitiro avo makuru ekushanda:

1. Arc Discharge uye Electrical-to-Thermal Energy Shanduko

1.1 Arc Kugadzira Mechanism

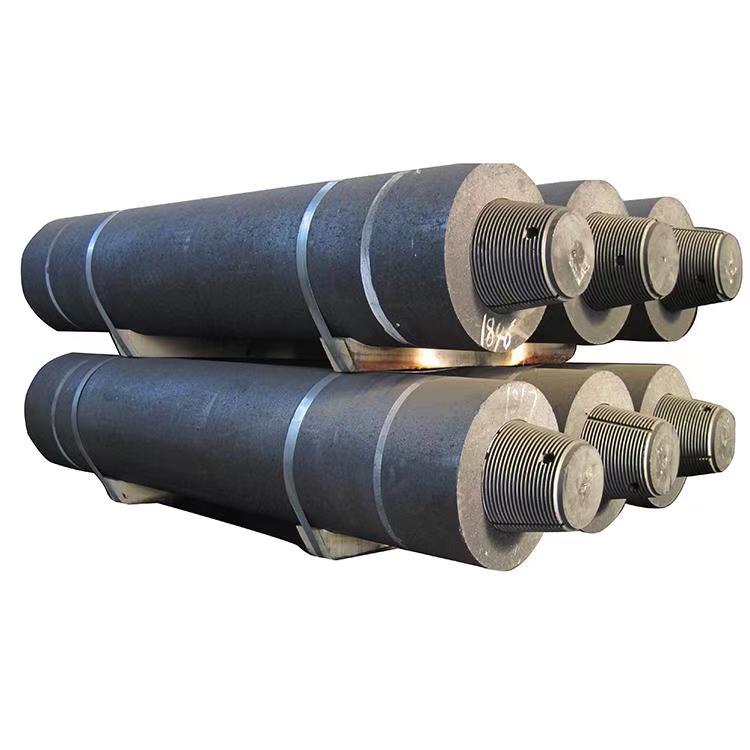

Kana UHP graphite electrodes yakabatanidzwa mumidziyo yekunyungudutsa (semuenzaniso, magetsi arc furnaces), anoita senge conductive media. High-voltage discharge inogadzira arc yemagetsi pakati pe electrode tip nechaji yevira (semuenzaniso, simbi yakaraswa, iron ore). Iyi arc ine conductive plasma chiteshi inoumbwa negasi ionization, ine tembiricha inodarika 3000 ° C-kure inodarika yakajairwa kupisa tembiricha.

1.2 Kufambiswa Kwemagetsi Kunoshanda

Kupisa kwakanyanya kunogadzirwa nearc kunonyungudutsa chaji yechoto. Iyo electrode 'yepamusoro magetsi conductivity (ine resistivity yakaderera se6-8 μΩ·m) inovimbisa kupera kushoma kwesimba panguva yekufambisa, optimizing mashandisirwo emagetsi. Mumagetsi arc furnace (EAF) kugadzira simbi, semuenzaniso, maelectrode eUHP anogona kuderedza kunyungudutsa kutenderera neanopfuura makumi matatu muzana, zvichiwedzera kugadzirwa.

2. Material Properties uye Performance Assurance

2.1 High-Temperature Structural Stability

Maelectrodes' epamusoro-tembiricha akasimba anobva muchimiro chawo checrystalline: akaturikidzana kabhoni maatomu anoumba covalent bond network kuburikidza nesp² hybridization, ine interlayer inosunga kuburikidza nemauto evan der Waals. Chimiro ichi chinochengetedza simba remagetsi pa 3000 ° C uye chinopa kusarudzika kwekupisa kwekuvhunduka (zvisinei nekushanduka kwetembiricha kusvika ku500 ° C/min), kupfuura maelectrode esimbi.

2.2 Kupokana neKuwedzera Kupisa uye Kukambaira

UHP maelectrodes anoratidza yakaderera coefficient of thermal kuwedzera (1.2×10⁻⁶/°C), kuderedza dimensional shanduko patembiricha yakakwirira uye kudzivirira mutswe kuumbwa nekuda kwekushushikana kwekupisa. Kuramba kwavo kunokambaira (kukwanisa kuramba deformation yepurasitiki pasi petembiricha yakakwira) inogadziriswa kuburikidza netsono coke raw material kusarudzwa uye advanced graphitization maitiro, kuve nechokwadi chekugadzikana kwedimensional panguva yakareba-mutoro wekushanda.

2.3 Oxidation uye Corrosion Resistance

Nekubatanidza antioxidants (semuenzaniso, borides, silicides) nekuisa machira epamusoro, tembiricha yekutanga oxidation ye electrodes inokwira pamusoro pe800°C. Kemikari inertness kurwisa slag yakanyungudutswa panguva yekunyungudutsa kunoderedza kunyanyisa kushandiswa kwemagetsi, kuwedzera hupenyu hwesevhisi kusvika 2-3 nguva yeyakajairika electrode.

3. Maitiro Kuenderana uye System Optimization

3.1 Yazvino Density uye Simba Capacity

UHP maelectrodes anotsigira density iripo inodarika 50 A/cm². Kana yapetwa neakakwirira-ekugona matransformer (semuenzaniso, 100 MVA), anogonesa magetsi echoto chimwe chete anodarika zana MW. Iyi dhizaini inomhanyisa mazinga ekupisa panguva yekunyungudutswa-semuenzaniso, kuderedza kushandiswa kwesimba patani yesilicon mukugadzirwa kweferrosilicon kusvika pasi pe8000 kWh.

3.2 Dynamic Response uye Maitiro Kudzora

Masisitimu emazuva ano ekunyungudutsa anoshandisa Smart Electrode Regulators (SERs) kuti irambe ichitarisisa nzvimbo ye electrode, kushanduka kwazvino, uye kureba kwearc, kuchengetedza mashandisirwo emagetsi mukati me1.5-2.0 kg/t simbi. Yakabatanidzwa nechoto chekutarisa mamiriro ekunze (semuenzaniso, CO/CO₂ ratios), izvi zvinogonesa electrode-charge coupling kunyatsoita.

3.3 System Synergy uye Energy Efficiency Enhancement

Kuendesa UHP maelectrodes kunoda kutsigira zvivakwa, zvinosanganisira akakwira-voltage magetsi ekupa masisitimu (eg, 110 kV yakananga yekubatanidza), tambo dzakatonhodzwa nemvura, uye mayunitsi ekuunganidza guruva anoshanda. Marara ekupisa kupisa matekinoroji (semuenzaniso, electric arc furnace off-gasi cogeneration) inosimudzira kugona kwesimba rose kusvika pamusoro pe60%, ichigonesa kushandiswa kwesimba.

Shanduro iyi inochengetedza hunyanzvi uku ichitevedzera chibvumirano chematemu edzidzo/maindasitiri, ichipa kujekeswa kune vateereri vane hunyanzvi.

Nguva yekutumira: May-06-2025