Ultra-yakakwirira simba graphite electrode, nekutsiva maelectrode emhangura negraphite electrode yekugadzira mold, kupfupisa zvakanyanya kutenderera kwekugadzira mold, kuwedzera kugadzirwa kwevashandi, uye kuderedza mutengo wekugadzira mold. Mumakore achangopfuura, nekuunzwa kwehukuro hwechokwadi uye hunyoro hwepamusoro-soro (nekutenderera kuri kuita kupfupika), zvinodiwa nevanhu zvekugadzira mold zvanga zvichikwira nekukwira. Nekuda kwekugumira kwakasiyana-siyana kwemhangura electrode pachayo, Iyo yakawedzera kutadza kuzadzisa zvinodiwa zvekusimudzira zveindasitiri yekuumbwa. Graphite, senge EDM electrode zvinhu, yakashandiswa zvakanyanya muindasitiri yekuumbwa nekuda kwezvakanaka zvayo senge yakakwira machinability, uremu huremu, kukurumidza kuumba, yakanyanya kuderera kuwedzera mwero, kurasikirwa kwakaderera uye kupfeka nyore. Hazvigoneki kuti ichatsiva mhangura electrodes.

1. Hunhu hweGraphite Electrode Materials

CNC machining inoratidzira kukurumidza kugadzirisa kumhanya, yakakwirira machinability uye nyore kupfeka. Iyo yekumhanyisa yekugadzira michina yegraphite ndeye 3 kusvika ka5 nguva yemhangura electrode, uye iyo chaiyo yekumhanyisa kumhanya inonyanya kukosha. Uyezve, simba rayo rakakwirira zvikuru. Kune ekupedzisira-yakakwirira (50 kusvika 90mm) uye Ultra-yakaonda (0.2 kusvika 0.5mm) maelectrodes, haawanzoita deformation panguva yekugadzirisa. Uyezve, muzviitiko zvakawanda, zvigadzirwa zvinoda kuve nemaitiro akanaka kwazvo. Izvi zvinoda kuti kana uchigadzira maelectrode, anofanirwa kuitwa seakakosha echirume maelectrode sezvinobvira. Nekudaro, kune akasiyana akavanzika makona ekuchenesa panguva yekugadzirwa kweakakosha echirume electrode. Pamusana pekugadzirisa zviri nyore pfuma ye graphite, dambudziko iri rinogona kugadziriswa nyore nyore uye nhamba ye electrode inogona kuderedzwa zvikuru, iyo electrode yemhangura haigone kubudirira.

2. Rapid EDM kuumba, kuwedzera kuduku kwekushisa uye kurasikirwa kwakaderera: Pamusana pekugadzirisa magetsi egraphite kupfuura yemhangura, kubuda kwayo kunokurumidza kupfuura yemhangura, kuva 3 kusvika ku5 nguva yemhangura. Uyezve, inogona kumirisana neyakakura ikozvino panguva yekubuda, iyo inonyanya kubatsira kune rough magetsi ekuburitsa machining. Zvichakadaro, pasi pehuwandu hwakafanana, uremu hwegraphite ndeye 1/5 nguva yemhangura, iyo inoderedza zvikuru mutoro weEDM. Iine mabhenefiti makuru mukugadzira maelectrodes makuru uye akakosha echirume emagetsi. Iyo sublimation tembiricha yegraphite ndeye 4200 ℃, inova 3 kusvika 4 nguva yemhangura (iyo sublimation tembiricha yemhangura ndeye 1100 ℃). Pakupisa kwakanyanya, shandura

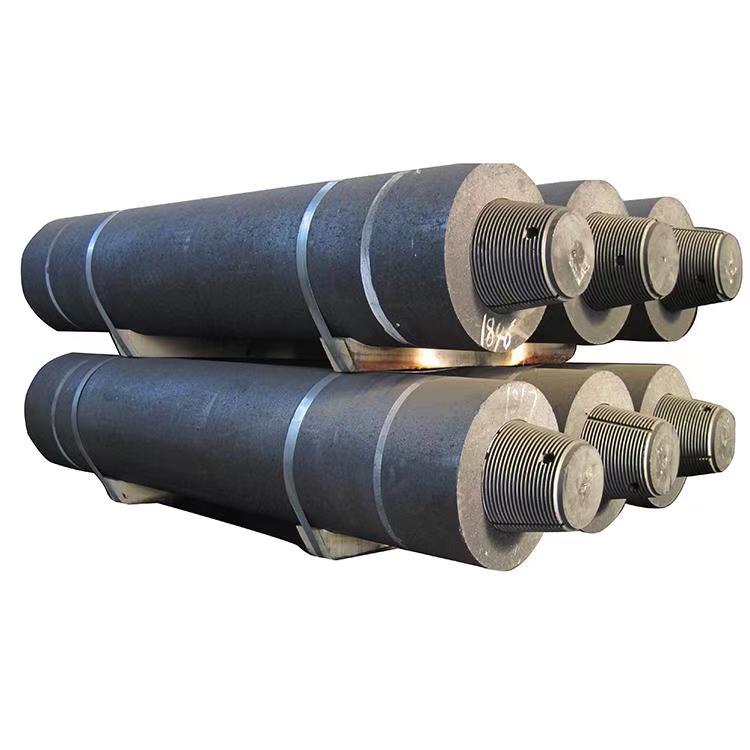

Ultra-yakakwirira simba graphite electrode

Iyo idiki zvakanyanya muchimiro (1/3 kusvika 1/5 yemhangura pasi pemamiriro akafanana emagetsi) uye haipfave. Simba rekubuda rinogona kuendeswa kune workpiece zvakanaka uye nekushandiswa kwakaderera. Nekuti simba re graphite rinowedzera pa tembiricha yakakwira, inogona kunyatso kudzikisa kurasikirwa kwekubuda (kurasikirwa kwegraphite ndeye 1/4 yemhangura), kuve nechokwadi chekugadzirisa kunaka.

3. Chiedza chechiedza uye mutengo wakaderera: Mukugadzirwa kwemari yekugadzira seti ye molds, iyo CNC machining nguva, EDM nguva, uye electrode kupfeka kwe electrode account yehuwandu hwehuwandu hwemari yose, uye izvi zvose zvinogadziriswa ne electrode material pachayo. Kuenzaniswa nemhangura, iyo machining speed uye EDM speed ye graphite zvose zviri zviviri 3 kusvika ku5 nguva yemhangura. Zvichakadaro, chimiro chekupfeka kushoma uye kugadzirwa kweiyo integral graphite electrode zvinogona kuderedza huwandu hwemagetsi, nekudaro kuderedza kushandiswa kwezvinhu uye machining nguva yemagetsi. Zvese izvi zvinogona kuderedza zvakanyanya mutengo wekugadzira we mold

2. Zvinodiwa uye Hunhu hweMechanical uye Magetsi Kugadziriswa kweGraphite Electrodes.

1. Kugadzirwa kwema electrode: Professional graphite electrode production inonyanya kushandisa maturusi emuchina wepamusoro-soro pakugadzirisa. Iwo maturusi emuchina anofanirwa kuve nekugadzikana kwakanaka, ane yunifomu uye yakagadzikana matatu-axis mafambiro pasina vibration. Uyezve, iko kutenderera kurongeka kwezvikamu senge shaft huru inofanirawo kuve yakanaka sezvinobvira. Iyo electrode inogona zvakare kugadziriswa pane zvakajairika muchina maturusi, asi maitiro ekunyora nzira yekushandisa akasiyana neaya emhangura electrode.

2.EDM magetsi ekubudisa machining graphite electrodes ndiwo carbon electrodes. Nemhaka yokuti girafu ine maitiro akanaka emagetsi, inogona kuchengetedza nguva yakawanda mumagetsi ekubudisa machining, iyo zvakare chimwe chezvikonzero nei graphite inoshandiswa se electrode.

3. Kugadziridza Hunhu hweGraphite Electrodes: Industrial graphite yakaoma uye ine brittle, inokonzera kusakara kwakanyanya pamaturusi panguva yeCNC machining. Kazhinji, zvinokurudzirwa kushandisa zvishandiso zvakaputirwa neakaoma alloy kana diamond. Kana rough machining graphite, chishandiso chinogona kuiswa zvakananga uye kubva kunze kwechishandiso. Nekudaro, panguva yekupedzisa machining, kudzivirira kucheka nekutsemuka, chishandiso chakareruka uye nzira yekukurumidza kuyambuka inowanzogamuchirwa.

Kazhinji kutaura, graphite haiwanzo kuputika kana kudzika kwekucheka kuri pasi pe 0.2mm, uye kunaka kwepamusoro kwemadziro emadziro kunogona kuwanikwawo. Iyo huruva inogadzirwa panguva yeCNC machining ye graphite electrodes yakakura uye inogona kupindira njanji yemutungamiri, zvigadziriso zvinotungamira uye maspindles emuchina wemuchina, nezvimwewo. Izvi zvinoda kuti girafu yekugadzira muchina chishandiso ive nemichina inopindirana yekubata neguruva remagraphite, uye dhizaini yekuisa chisimbiso yemuchina inofanirawo kuva yakanaka nekuti graphite ine chepfu. Graphite poda chinhu chinonzwa zvakanyanya nekuita kwemakemikari. Resistivity yayo inoshanduka munzvimbo dzakasiyana, zvichireva kuti kukosha kwayo kunosiyana. Zvisinei, pane chinhu chimwe chinoramba chiripo: graphite powder ndeimwe yeakanakisa isiri-metallic conductive zvinhu. Chero bedzi iyo graphite poda yakachengetwa muchinhu chinodzivirira pasina kukanganisa, seshinda yakatetepa, icharamba ichiiswa magetsi. Asi chii chinonzi kuramba kukosha? Ikoko hakuna chimiro chakajeka cheichi kukosha kana, nokuti kunaka kwe graphite powder kunosiyana, uye kupikisa kukosha kwe graphite powder inoshandiswa muzvinhu zvakasiyana-siyana uye nharaunda zvichave zvakasiyana.

Iwe unogona kunge usingazivi kuti high-purity graphite powder inewo maitiro ekuitisa:

Kazhinji, rubber is insulating. Kana conductivity yemagetsi ichidiwa, conductive zvinhu zvinoda kuwedzerwa. Graphite poda ine yakanakisa magetsi conductivity uye lubricating demolding zvivakwa. Graphite inogadzirwa kuita graphite poda, ine yakanakisa lubricating uye conductive zvivakwa. Iyo yakakwirira kuchena kwe graphite poda, zviri nani kuita kwayo conductive. Mafekitori mazhinji akakosha ezvigadzirwa zverabha anoda conductive rubber. Bva, graphite powder inogona kuwedzerwa ku rabha kuti ifambise magetsi here? Mhinduro ndeyokuti hongu, asi panewo mubvunzo: Ndeipi chikamu che graphite powder mu rubber? Mamwe makambani anoshandisa chikamu chisingadariki makumi matatu kubva muzana, chinoiswa kune zvigadzirwa zverabha zvisingapfeki sematayi emotokari, nezvimwewo. Kune zvakare mafekitori akakosha erabha anoshandisa chikamu che100%. Zvigadzirwa zvakadaro chete zvinogona kuitisa magetsi. Nheyo yekutanga ye conductivity ndeyekuti conductor haigone kukanganiswa, senge waya. Kana ikavhiringwa nepakati, haizoisirwe magetsi. Iyo conductive graphite poda mu conductive rubber ndiyo conductor Kana iyo graphite poda yakavharwa ne insulating rubber, haichazofambisi magetsi. Nokudaro, kana chikamu che graphite powder chakanyanya kuderera, conductive effect inogona kunge yakashata.

Graphite poda chinhu chinonzwa zvakanyanya nekuita kwemakemikari. Resistivity yayo inoshanduka munzvimbo dzakasiyana, zvichireva kuti kukosha kwayo kunosiyana. Zvisinei, pane chinhu chimwe chinoramba chiripo: high-purity graphite powder ndeimwe yezvakanakisa zvisiri zvesimbi conductive zvinhu. Chero bedzi iyo graphite poda yakachengetwa muchinhu chinodzivirira pasina kukanganisa, seshinda yakatetepa, icharamba ichiiswa magetsi. Asi chii chinonzi kuramba kukosha? Ikoko hakuna chimiro chakajeka cheichi kukosha kana, nokuti kunaka kwe graphite powder kunosiyana, uye kupikisa kukosha kwe graphite powder inoshandiswa muzvinhu zvakasiyana-siyana uye nharaunda zvichave zvakasiyana.

Nguva yekutumira: Chivabvu-09-2025