1.EDM maitiro ezvinyorwa zvegraphite.

1.1.Discharge machining speed.

Graphite isimbi isiri-metallic ine yakanyanya kunyungudika ye3, 650 ° C, nepo mhangura ine nzvimbo yekunyunguduka ye1, 083 ° C, saka iyo graphite electrode inokwanisa kutsungirira makuru ekuseta mamiriro.

Kana nzvimbo yekubuditsa uye chiyero chehukuru hwe electrode yakakura, zvakanakira zvepamusoro rough machining e graphite zvinhu zvinonyanya kuoneka.

Iyo yekupisa conductivity ye graphite ndeye 1/3 iyo yemhangura, uye kupisa kunogadzirwa panguva yekuyerera kunogona kushandiswa kubvisa zvinhu zvesimbi zvakanyanya.Nokudaro, kushandiswa kwekugadzirisa kwegraphite kwakakwirira kudarika iyo yemhangura electrode mukati uye yakanaka kugadzirisa.

Zvinoenderana nechiitiko chekugadzirisa, iyo yekuburitsa yekumhanyisa kumhanya kwegraphite electrode ndeye 1.5 ~ 2 nguva nekukurumidza kupfuura iyo yemhangura electrode pasi pemamiriro ekushandisa.

1.2.Kushandiswa kweElectrode.

Graphite electrode ine hunhu hunogona kumirisana nemamiriro epamusoro azvino, mukuwedzera, pasi pemamiriro ekugadzirisa kwakakodzera, kusanganisira kabhoni simbi workpieces inogadzirwa panguva yekubvisa machining mumukati uye inoshanda fluid pakuora kwekushisa kwekabhoni particles, iyo polarity effect, pasi. chiito chekubvisa chikamu mumukati, kabhoni particles inonamatira kune electrode pamusoro kuti iite inodzivirira layer, simbisa iyo graphite electrode mukurasikirwa kudiki muhutsinye machining, kana kunyange "zero tsvina".

Iyo huru electrode kurasikirwa muEDM kunobva kune rough machining.Kunyangwe chiyero chekurasikirwa chakakwira mumamiriro ekugadzirisa ekupedzisa, kurasikirwa kwese kwakaderera zvakare nekuda kwediki machining mvumo yakachengeterwa zvikamu.

Kazhinji, kurasikirwa kwe graphite electrode ishoma pane yemhangura electrode muhutsinye machining emazuva ano makuru uye zvishoma kudarika iyo yemhangura electrode mukupedzisa machining.Iyo electrode kurasikirwa kwegraphite electrode yakafanana.

1.3.Hunhu hwepamusoro.

Iyo chidimbu dhayamita ye graphite zvinhu inokanganisa zvakananga pamusoro peiyo EDM.Iyo diki iyo dhayamita ndeye, iyo yakaderera iyo yepamusoro roughness inogona kuwanikwa.

Makore mashoma apfuura uchishandisa particle phi 5 microns mudhayamita graphite zvinhu, iyo yakanakisa nzvimbo inogona chete kuwana VDI18 edm (Ra0.8 microns), mazuva ano dhayamita yezviyo zve graphite zvinhu zvakakwanisa kuwana mukati me3 microns ye phi, iyo yakanakisa nzvimbo. inogona kuwana yakagadzikana VDI12 edm (Ra0.4 mu m) kana yakawanda sophisticated level, asi iyo graphite electrode kugirazi edm.

Iyo mhangura yemhangura ine yakaderera resistivity uye compact chimiro, uye inogona kugadziriswa yakadzikama pasi pemamiriro akaoma.Kushata kwepamusoro kunogona kunge kuri pasi peRa0.1 m, uye inogona kugadziriswa negirazi.

Saka, kana machining ekuyerera achitevera yakanyanyisa kunaka kwepamusoro, inonyanya kukodzera kushandisa mhangura se electrode, iyo ndiyo inonyanya kukosha yemhangura electrode pamusoro pegraphite electrode.

Asi electrode yemhangura pasi pemamiriro ehukuru huripo huripo, iyo electrode yepamusoro iri nyore kuva yakaoma, inoratidzika kunyange yakatsemuka, uye girafu zvinhu hazvizove nedambudziko iri, iyo yepamusoro roughness inodiwa yeVDI26 (Ra2.0 microns) pamusoro pekugadzira mold, uchishandisa. graphite electrode inogona kuitwa kubva kune yakaomarara kusvika kune yakanaka kugadzirisa, inoziva iyo yunifomu yepasi mhedzisiro, kuremara kwepamusoro.

Mukuwedzera, nekuda kwechimiro chakasiyana che graphite nemhangura, iyo yepamusoro inobuda corrosion point ye graphite electrode inowanzoitika kupfuura iyo yemhangura electrode.Naizvozvo, kana iyo yakafanana pamusoro roughness yeVDI20 kana pamusoro ichigadziriswa, iyo yepamusoro granularity ye workpiece yakagadziridzwa negraphite electrode inonyanya kusiyanisa, uye iyi tsanga pamusoro peiyo mhedzisiro iri nani pane inobuda pamusoro peiyo copper electrode.

1.4.The machining kururama.

Iyo coefficient yekuwedzera kwekupisa kwe graphite zvinhu idiki, iyo coefficient yekupisa kwekuwedzera kwemhangura yemhangura ndeye 4 nguva ye graphite zvinhu, saka mukubuda kwekuyerera, graphite electrode haina kukonzeresa deformation kupfuura electrode yemhangura, inogona kuwana yakagadzikana uye yakagadzikana. yakavimbika kugadzirisa kururama.

Kunyanya kana mbabvu yakadzika uye yakamanikana ichigadziriswa, tembiricha yakakwira yenzvimbo inoita kuti electrode yemhangura kukotama nyore, asi electrode yegraphite haidaro.

Kune electrode yemhangura ine yakakura kudzika-dhayamita reshiyo, kumwe kupisa ukoshi hwekuwedzera hunofanirwa kubhadharwa kugadzirisa saizi panguva yekumisikidza machining, nepo graphite electrode isingadiwi.

1.5.Electrode uremu.

Iyo graphite zvinhu haina kusimba kupfuura mhangura, uye huremu hwe graphite electrode yevhoriyamu imwechete inongova 1/5 yeiyo ye electrode yemhangura.

Zvinogona kuonekwa kuti kushandiswa kwe graphite kwakanyatsokodzera kune electrode ine vhoriyamu yakakura, iyo inoderedza zvikuru mutoro we spindle ye EDM machine tool.Iyo electrode haizokonzeri kusagadzikana mukusungirira nekuda kwehuremu hwayo hukuru, uye ichaburitsa kutsauka kwekuchinjika mukugadzirisa, etc. Zvinogona kuonekwa kuti zvakakosha zvikuru kushandisa graphite electrode muhukuru hwekugadzira mold.

1.6.Electrode kugadzira kuoma.

Iyo machining kuita kwegraphite zvinhu zvakanaka.Iyo yekucheka kuramba ndeye 1/4 chete yemhangura.Pasi pemamiriro ekugadzirisa ekugadzirisa, kushanda kwekugadzira graphite electrode ndeye 2 ~ 3 nguva yemhangura electrode.

Graphite electrode iri nyore kujekesa Angle, uye inogona kushandiswa kugadzirisa iyo workpiece iyo inofanirwa kupedzwa neakawanda maelectrode kuita imwechete electrode.

Iyo yakasarudzika chidimbu chimiro che graphite zvinhu inodzivirira maburrs kuti asaitike mushure mekugadzira electrode kugaya uye kugadzira, iyo inogona kuzadzisa zvakanangana nezvinodiwa zvekushandisa kana maburrs asingabviswe nyore mumhando yakaoma yekuenzanisira, nekudaro achibvisa maitiro ekunyora kwemagetsi e electrode uye kudzivirira chimiro. shanduko uye saizi kukanganisa kunokonzerwa nekupenya.

Zvinofanira kucherechedzwa kuti, nekuti graphite ihuruva kuunganidza, milling graphite inoburitsa guruva rakawanda, saka muchina wekugaya unofanirwa kuve nechisimbiso uye guruva rekuunganidza mudziyo.

Kana zvakakosha kushandisa edM kugadzirisa graphite electrode, kushanda kwayo hakuna kunaka semhangura yemhangura, kukurumidza kucheka kunenge 40% inononoka kupfuura mhangura.

1.7.Electrode kuiswa uye kushandiswa.

Graphite zvinhu zvine yakanaka yekubatanidza pfuma.Inogona kushandiswa kubatanidza graphite nechigadziriso nekukuya electrode uye kuburitsa, iyo inogona kuchengetedza maitiro ekugadzira screw hole pane electrode zvinhu uye kuchengetedza nguva yekushanda.

Iyo graphite zvinhu zvine brittle, kunyanya diki, nhete uye refu electrode, iyo iri nyore kutyora kana ichiiswa kunze kwesimba panguva yekushandiswa, asi inogona pakarepo kuziva kuti electrode yakakuvadzwa.

Kana iri electrode yemhangura, inongokotama uye isingaputsi, iyo ine ngozi zvikuru uye yakaoma kuwana mukushandiswa kwekushandiswa, uye inotungamira nyore kune chimedu che workpiece.

1.8.Mutengo.

Mhangura yemhangura chinhu chisingadzokerikezve, maitiro emitengo anowedzera uye anodhura, nepo mutengo we graphite zvinhu unowanzo kudzikama.

Mutengo wemhangura wezvinhu uchikwira mumakore achangopfuura, vagadziri vakuru ve graphite vanovandudza maitiro mukugadzirwa kwegraphite vanoita mukana wekukwikwidza, ikozvino, pasi peiyo vhoriyamu imwechete, kuwanda kwe graphite electrode mutengo wezvinhu uye mutengo wemhangura electrode zvinhu zvakaringana, asi. iyo graphite inogona kubudirira kugadzirisa, pane kushandiswa kwemhangura electrode kuchengetedza nhamba huru yemaawa ekushanda, zvakaenzana nekuderedza mari yekugadzira zvakananga.

Kupfupisa, pakati pe8 edM maitiro e graphite electrode, zvakanakira zvaro zviri pachena: kushanda kwemagetsi ekugaya uye kuburitsa kuburitsa kunonyanya kunaka kupfuura iyo yemhangura electrode;electrode hombe ine huremu hudiki, yakanaka dimensional kugadzikana, mutete electrode haisi nyore kukanganisa, uye magadzirirwo epamusoro ari nani pane electrode yemhangura.

Izvo zvisingabatsiri zvezvinhu zve graphite ndezvekuti hazvina kukodzera kushandiswa kwakanaka kwepasi pasi peVDI12 (Ra0.4 m), uye kushanda kwekushandisa edM kuita electrode yakaderera.

Nekudaro, kubva pamaonero anoshanda, chimwe chezvikonzero zvakakosha chinokanganisa kusimudzira kunobudirira kwezvinhu zvegraphite muChina ndechekuti yakakosha graphite yekugadzirisa muchina unodiwa kumilling electrode, inoisa mberi zvinodiwa zvitsva zvekugadzira michina yemabhizinesi ekuumbwa, mamwe mabhizinesi madiki. anogona kunge asina chimiro ichi.

Kazhinji, mabhenefiti emagraphite electrode anovhara huwandu hukuru hweedM kugadzirisa zviitiko, uye akakodzera kufarirwa uye kushandiswa, aine mabhenefiti enguva refu.Kushaikwa kwekunaka kwepamusoro pekugadzirisa kunogona kugadzirwa nekushandiswa kwemhangura electrodes.

2.Kusarudzwa kwe graphite electrode zvinhu zveEDM

Kune zvigadzirwa zvegraphite, pane kunyanya zvinotevera zviratidzi zvina zvinotarisa zvakananga kuita kwezvishandiso:

1) Avhareji yechidimbu dhayamita yechinhu

Ivhareji yepakati dhayamita yezvinyorwa inokanganisa zvakananga mamiriro ekubuda kwezvinhu.

Iyo diki yeavhareji yechikamu che graphite zvinhu, iyo yakawanda yunifomu yekuburitsa, iyo yakanyanya kugadzikana mamiriro ekuburitsa, zviri nani kunaka kwepamusoro, uye kushoma kurasikirwa.

Iyo yakakura yeavhareji saizi yezvikamu ndeye, iyo iri nani yekubvisa mwero inogona kuwanikwa muhutsinye machining, asi iyo yepamusoro mhedzisiro yekupedzisa haina kunaka uye kurasikirwa kwe electrode kwakakura.

2) Simba rekukotama rezvinhu

Simba rekushanduka-shanduka rechinhu chiratidziro chakananga chesimba rayo, zvichiratidza kusimba kwechimiro chayo chemukati.

Izvo zvinhu zvine simba repamusoro zvine zvakanakira discharge resistance performance.Kune electrode nehupamhi hwepamusoro, zvinhu zvine simba rakanaka zvinofanira kusarudzwa sezvinobvira.

3) Shore kuoma kwezvinhu

Graphite yakaoma kudarika zvigadzirwa zvesimbi, uye kurasikirwa kwechigadzirwa chekucheka kwakakura kudarika kwesimbi yekucheka.

Panguva imwecheteyo, kuoma kwepamusoro kwe graphite zvinhu mukubuda kwekurasikirwa kwekutonga kuri nani.

4) The inherent resistivity yezvinhu

Mwero wekuburitsa we graphite zvinhu zvine yakakwira inherent resistivity inononoka pane iyo ine yakaderera resistivity.

Iyo yakakwira iyo inherent resistivity, iyo idiki yekurasikirwa kwe electrode, asi iyo yakakwirira iyo inherent resistivity, kugadzikana kwekubuda kunokanganiswa.

Parizvino, kune magiredhi akawanda akasiyana-siyana egraphite anowanikwa kubva kune vanotungamira pasi rose vanotengesa magraphite.

Kazhinji maererano nechiyero chechidimbu chechidimbu chezvigadzirwa zve graphite kuti zvigadziriswe, chidimbu chechidimbu ≤ 4 m inotsanangurwa seyakanaka graphite, zvikamu mu 5 ~ 10 m inotsanangurwa sepakati graphite, zvimedu mu 10 m pamusoro zvinotsanangurwa se coarse graphite.

Iyo diki iyo chidimbu dhayamita ndeye, iyo inodhura iyo zvinhu, iyo yakanyanya kufanirwa graphite zvinhu zvinogona kusarudzwa maererano nezvinodiwa uye mutengo weEDM.

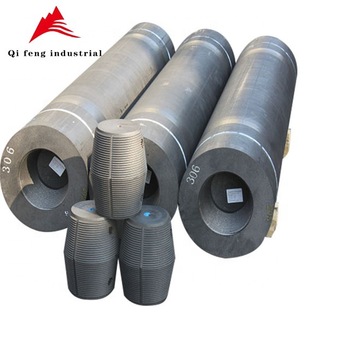

3.Kugadzirwa kwe graphite electrode

Iyo graphite electrode inonyanya kugadzirwa nekugaya.

Kubva pakuona kwekugadzira tekinoroji, graphite nemhangura zvinhu zviviri zvakasiyana, uye maitiro avo akasiyana ekucheka anofanirwa kuve nyanzvi.

Kana iyo graphite electrode inogadziriswa nemaitiro emagetsi emhangura, matambudziko achazoitika, sekuputsika kazhinji kwepepa, izvo zvinoda kushandiswa kwezvishandiso zvakakodzera zvekucheka uye zvimiro zvekucheka.

Machining graphite electrode pane copper electrode tool kupfeka, pakufunga kwehupfumi, kusarudzwa kwecarbide tool ndiyo yakanyanya hupfumi, sarudza diamond yekupfekedza chishandiso (inonzi graphite banga) mutengo unodhura, asi madhaimondi ekuputira chishandiso hupenyu hurefu hwesevhisi, yakakwirira kugadzirisa chaiyo, kubatsirika kwehupfumi kwese kwakanaka.

Saizi yekumberi Angle yechishandiso inokanganisawo hupenyu hwayo hwesevhisi, iyo 0 ° yekumberi Angle yechishandiso ichakwira kusvika 50% yakakwira kupfuura iyo 15 ° yekumberi Angle yehupenyu hwesevhisi, kucheka kugadzikana kuri nani, asi iyo yakakura iyo Angle, zviri nani iyo machining pamusoro, kushandiswa kwe15 ° Angle yechishandiso kunogona kuwana yakanakisa machining pamusoro.

Iko kumhanya kwekucheka mukugadzira kunogona kugadziriswa maererano nechimiro che electrode, kazhinji 10m / min, yakafanana nekugadzirwa kwealuminium kana plastiki, chigadziro chekucheka chinogona kuva chakananga uye kunze kwechigadziro chekushanda mu rough machining, uye chiitiko cheAngle. kudonha uye kupatsanurwa zviri nyore kuitika mukupedzisa machining, uye nzira yekureruka banga kufamba nekukurumidza inogamuchirwa.

Graphite electrode mukucheka inoburitsa guruva rakawanda, kuitira kudzivirira graphite zvimedu zvinofemerwa muchina spindle uye screw, pane maviri makuru mhinduro parizvino, imwe ndeye kushandisa yakakosha graphite yekugadzirisa muchina, imwe yacho ndiyo yakajairwa kugadzirisa nzvimbo. refit, yakashongedzerwa nechinhu chakakosha chekuunganidza guruva.

Muchina wakakosha we graphite wepamusoro wekugaya pamusika une hunyanzvi hwekugaya uye unogona kupedzisa zviri nyore kugadzira kwema electrode akaomarara nehupamhi hwepamusoro uye kunaka kwepamusoro.

Kana EDM ichidikanwa kuita graphite electrode, inokurudzirwa kushandisa yakanaka graphite zvinhu nediki particle diameter.

Iyo machining performance yegraphite haina kunaka, iyo idiki iyo dhayamita yechidimbu ndiyo, iyo yakakwirira yekucheka kugona kunogona kuwanikwa, uye matambudziko asina kujairika akadai sekugara achipwanya waya uye mupendero wepamusoro anogona kudzivirirwa.

4.EDM parameters ye graphite electrode

Kusarudzwa kwe EDM parameters ye graphite nemhangura yakasiyana chaizvo.

Izvo zviyero zveEDM zvinonyanya kusanganisira ikozvino, pulse width, pulse gap uye polarity.

Izvi zvinotevera zvinotsanangura hwaro hwekushandisa zvine musoro kweaya maparamendi makuru.

Ikozvino density ye graphite electrode inowanzoita 10 ~ 12 A/cm2, yakakura kudarika iyo ye electrode yemhangura.Nokudaro, mukati mehuwandu hwemazuva ano hunobvumirwa munzvimbo inoenderana, iyo yakakura inosarudzwa inosarudzwa, iyo inokurumidza kukurumidza kukurumidza kukurumidza kubudiswa kwe graphite, iyo idiki kurasikirwa kwe electrode kuchava, asi kusvibiswa kwepamusoro kuchave kwakakura.

Iyo yakakura iyo pulse hupamhi ndeye, yakaderera iyo kurasikirwa kwe electrode kuchave.

Nekudaro, iyo yakakura pulse hupamhi ichaita kuti kugadzikana kwekugadzirisa kunyanye, uye kumhanya kwekugadzirisa kunonoke uye pamusoro rougher.

Kuti uve nechokwadi chekurasikirwa kwemagetsi emagetsi panguva yekugadzira hutsinye, hupamhi hwepurusi hwakakura hunowanzo shandiswa, hunogona kunyatsoona kurasikirwa kwakaderera kwema graphite electrode kana kukosha kuri pakati pezana ne300 US.

Kuti uwane yakanaka yepamusoro uye yakagadzikana yekuburitsa mhedzisiro, diki pulse upamhi hunofanira kusarudzwa.

Kazhinji, kupuruzira kwe graphite electrode kunenge 40% yakaderera pane yemhangura electrode.

Iyo pulse gap inonyanya kukanganisa kuburitsa machining kumhanya uye machining kugadzikana.Iyo yakakura kukosha, zvirinani kugadzikana kwemuchina kuchava, izvo zvinobatsira pakuwana zvirinani pamusoro pekufanana, asi kumhanya kwekugadzira kuchaderedzwa.

Pasi pemamiriro ekuvimbisa kugadzikana kwekugadzirisa, kushanda kwepamusoro-soro kunogona kuwanikwa nekusarudza diki pfupa gap, asi kana mamiriro ekubuda asina kugadzikana, kushanda kwepamusoro kwekugadzirisa kunogona kuwanikwa nekusarudza gap guru repulse.

Mu graphite electrode discharge machining, pulse gap uye pulse width inowanzoiswa pa1: 1, nepo mumhangura electrode machining, pulse gap uye pulse width zvinowanzoiswa pa1: 3.

Pasi pekugadzika kwegraphite kugadzirisa, chiyero chekufananidza pakati pepulse gap uye pulse wide inogona kugadziridzwa kusvika 2:3.

Muchiitiko chechidiki chekuputika, zvinobatsira kuumba chifukidzo chekuvhara pamusoro pe electrode surface, iyo inobatsira kuderedza kurasikirwa kwe electrode.

Iyo polarity kusarudzwa kwe graphite electrode muEDM inonyanya kufanana neyemhangura electrode.

Zvinoenderana neiyo polarity effect yeEDM, positive polarity machining inowanzoshandiswa kana machining die steel, kureva kuti, electrode yakabatanidzwa kune yakanaka pole yemagetsi, uye workpiece yakabatanidzwa kune yakaipa danda remagetsi.

Uchishandisa yakakura ikozvino uye pulse hupamhi, kusarudza yakanaka polarity machining inogona kuwana yakaderera yakaderera electrode kurasikirwa.Kana iyo polarity isiriyo, kurasikirwa kwe electrode kuchava kukuru kwazvo.

Chete kana iyo yepamusoro inofanirwa kugadziriswa zvishoma pane VDI18 (Ra0.8 m) uye hupamhi hwepurusi iduku kwazvo, iyo yakaipa polarity processing inoshandiswa kuti iwane kunaka kwepamusoro, asi kurasikirwa kwe electrode kwakakura.

Iye zvino CNC edM muchina maturusi ane graphite discharge machining paramita.

Iko kushandiswa kwemagetsi parameter kune hungwaru uye inogona kugadzirwa otomatiki nehunyanzvi sisitimu yemuchina wemuchina.

Kazhinji, muchina unogona kugadzirisa optimized processing parameters nekusarudza zvinhu zviviri, rudzi rwemashandisirwo, kukosha kwepamusoro uye kuisa nzvimbo yekugadzirisa, kudzika kwekugadzirisa, electrode size scaling, etc. Panguva yepurogiramu.

Seti yegraphite electrode yeedm muchina chishandiso raibhurari yakapfuma yekugadzirisa paramita, iyo yemhando yemhando inogona kusarudza mune coarse graphite, graphite, graphite inoenderana neyakasiyana-siyana yebasa rekushandisa, kupatsanura rudzi rwekunyorera chiyero, yakadzika groove, inopinza poindi, hombe. nharaunda, hombe mhango, senge yakanaka, inopawo kurasikirwa kwakaderera, chiyero, kugona kwakanyanya uye zvichingodaro pamhando dzakawanda dzekugadzirisa sarudzo yekutanga.

5. Mhedziso

Iyo itsva graphite electrode zvinhu zvakakosha kufarirwa nesimba uye zvakanakira zvaro zvichazivikanwa zvishoma nezvishoma uye kugamuchirwa neindasitiri yekugadzira mold.

Iko kusarudzwa kwakaringana kwegraphite electrode zvinhu uye kuvandudzwa kweanoenderana tekinoroji zvinongedzo zvinounza kushanda kwepamusoro, mhando yepamusoro uye yakaderera mutengo wekubatsira kumabhizinesi ekugadzira mold.

Nguva yekutumira: Zvita-04-2020